Before The Engine, Before Problems Start

Separ fuel water separators focus on reducing the wear and tear on the fuel system to ensure long-term and trouble free operation for engines and generators. It is the first line of defense to remove water and particulate in diesel fuel, which lead to unexpected downtime and costly repairs.

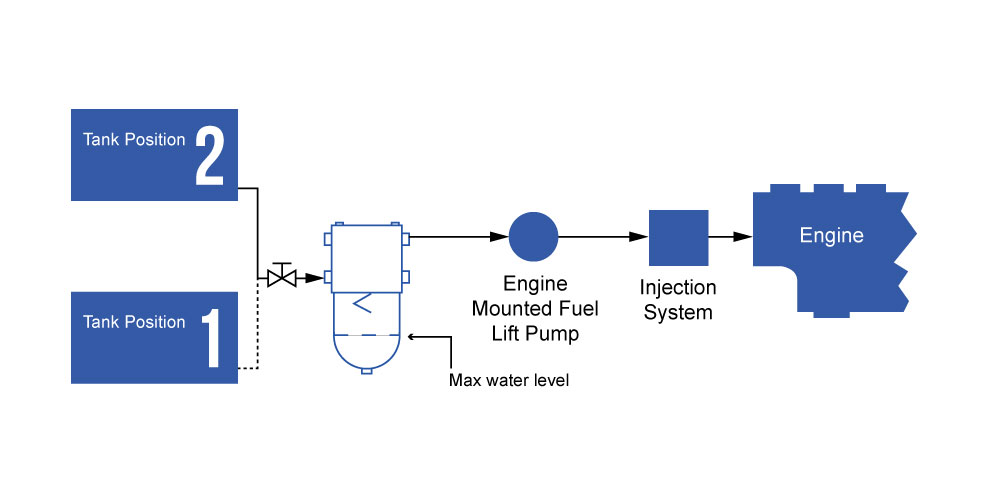

When installed between the tank and the engine, the staged filtration helps avoid fuel-related failure and prolongs the life of engine-mounted filters. Separ Filter keeps engines running reliably in the power generation, agricultural, marine, construction, mining, transportation, government, and more commercial industries.

Single and Duplex Filter Assembly

Separ fuel water separators are available in various single and duplex models to suit virtually any application. Simple installation and maintenance has proven the filter assembly versatile for setups in the OEM and aftermarket setups.

The LKF and EVO10 are designed as single, lightweight assemblies that are ideal for compact, mobile equipment and transportation. The SWK2000 offers both single and duplex assemblies for almost all diesel engine applications.

A duplex assembly is recommended for applications requiring continuous diesel power (e.g. standby power generators, vessels with only one propulsion engine or generators used for prime power). The secondary filter in this assembly is a backup. Manually switch use to the secondary filter to quickly resume engine operation, while the other filter can be scheduled for maintenance at a more convenient time.

Sizing By Flow Rate

Separ offers the highest flow rate, at the lowest pressure drop, within the smallest footprint. When selecting a filter assembly size and model, the filter assembly's flow rate must be greater than the lift pump's flow rate (not the burn rate). Confirm the burn rate with your engine dealer or Contact Us for assistance.